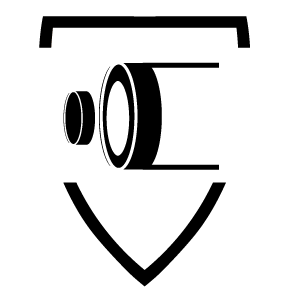

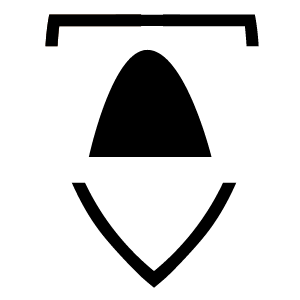

The Fiocchi Group, thanks to Baschieri & Pellagri’s R&D department, has identified a range of technical solutions to manufacture wads made with 100% biodegradable materials, with technical performance in line or better than using traditional plastic materials.

“Launching this project only one year after welcoming Baschieri & Pellagri to the Fiocchi Group” – tells Daniele Palmieri, Chief Marketing & Commercial Officer – “represents a significant milestone and a concrete sign of integration and synergies between two great companies that joined their competencies to deliver innovation according to the two main drivers of our Group’s mission: GO GREEN and GO PREMIUM. I’m extremely proud to be part of a team that leads with an innovative process according to global and relevant trends like environmental sustainability, as we continue to drive solutions to offer to our passionate users high quality products”.

Alessandro Fioravanti, Baschieri & Pellagri General Manager, highlights how “the cooperation with the University of Bologna, in particular with the Centre for Advanced Mechanics and Materials (CIRI-MAM) and Professor Maurizio Fiorini gave us the opportunity to share inter-disciplinary competencies needed for such a complex project. The development of new biodegradable polymeric compounds was possible thanks to the research contract signed with CIRI - MAM of the University of Bologna -Alma Mater. By exchanging knowledge and competences between private/public enterprise and Academia we have been able to fuel the growth and the value we bring to public and private enterprises”.

“In this project - explains Marco Manfredi, Baschieri & Pellagri R&D Director – B&P’s technical team sourced 100% biodegradable material for creating a complete range of components for shotshell target and hunting wads. To ensure excellent ballistic performance, both internal and external, we carefully and consistently tested with various shotguns at many different climatic conditions, humidity and temperatures, both pilot products and finished industrial samples. We are extremely proud of the results achieved but also proud to give our contributions to the development of the Group’s R&D”.

“Fiocchi Group’s commitment towards green products comes decades of experience from the centrefire products – comments Costantino Fiocchi, Group’s Chief Technical Officer – with the manufacturing of lead-free and heavy-metal free primers (called ZP, Zero Pollution) and with the development of a wide range of lead-free bullets (copper alloys, steel, tin, bismuth). The production of wads made with 100% biodegradable material is therefore the logical step towards our commitment to more modern and sustainable materials”.

Starting from January 2022, the two brands, Baschieri & Pellagri and Fiocchi, will present to the world their respective portfolio of branded products using these new biodegradable wads, thus reinforcing the strong brand positioning, innovation and quality built over 150 years of unparalleled passion and heritage.

IT

IT